Quality Control

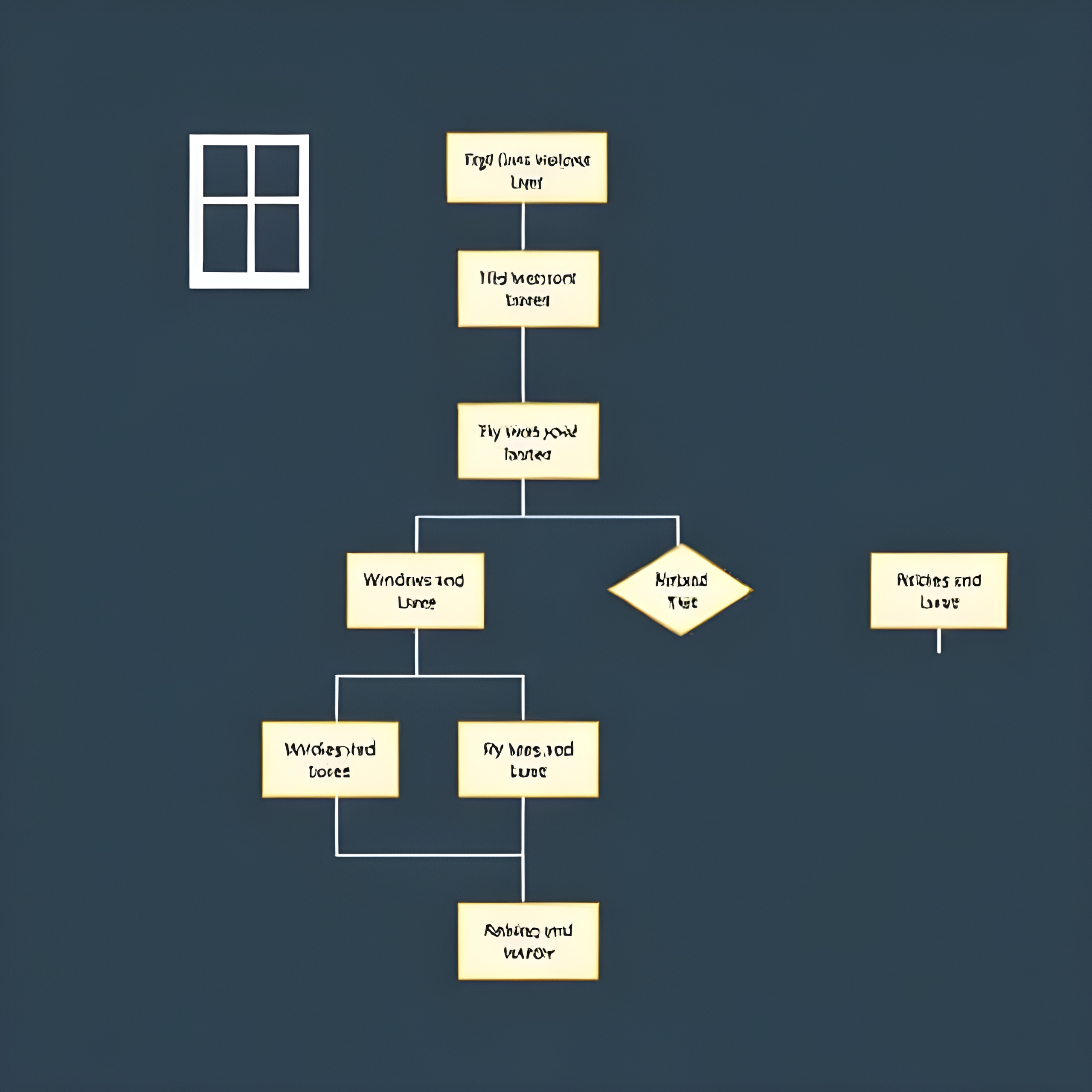

Step-by-Step Quality Inspection Process

Preparation and Setup

The quality control inspector prepares the clean, bright workspace, ensuring that all tools and equipment are ready for use. The environment is kept orderly to maintain a professional and efficient inspection process.

Initial Visual Inspection

The inspector carefully examines the pleated window blind for any visible defects, such as fabric inconsistencies, wrinkles, or color mismatches. This step ensures that the product looks flawless at first glance.

Material Integrity Check

The inspector checks the material for any signs of damage or wear. This includes verifying the quality and strength of the fabric, ensuring it meets the required durability standards.

Functionality Testing

The inspector tests the mechanical components of the window blind, including the operating mechanism, ensuring it works smoothly and efficiently without any issues.

Final Inspection and Packaging

After confirming the product meets all quality standards, the window blind is carefully folded and packaged, ready for shipment. Any minor defects or issues discovered during the inspection are corrected before packaging.

Approval for Shipment

Only after passing this rigorous inspection process is the window blind approved for shipment, ensuring customers receive only the highest quality products.